How to Adjust Sewing Machine Tension for Perfect Stitches

This post may contain affiliate links, which means I’ll receive a commission if you purchase through my links, at no extra cost to you. I sometimes receive free products for review. Please read disclosure for more information.

To create the perfect stitch, you need to know how to adjust your sewing machine tension.

Why? Because poorly adjusted tension can ruin any sewing project.

You might end up with huge thread loops on the bottom of the fabric or find the lower bobbin thread pulled to the top of the fabric. The stitches may even be too loose or too tight, causing the fabric to pucker.

As a beginner sewist, I remember being mystified about the idea of tension. For the first little while, my Brother sewing machine remained stuck on a “4” because I was so afraid I’d ruin something if I changed it.

All was great until I decided to change to a thick fabric sewing project with a heavyweight thread.

After troubleshooting the poor stitch quality, I fearfully decided it was time to adjust the tension on my Brother sewing machine to address the issue.

If you, too, are afraid of sewing tension, have no fear!

This sewing machine tension guide will explain what sewing machine tension is and when to adjust it, what other issues may be causing stitching problems, and finally, how to adjust sewing machine tension to achieve the best results.

Defining Tension

Sewing machine tension, or stitch tension, is the pressure applied to the top and bobbin threads as they pass through a sewing machine.

How Threads Interact to Create Tension

Two threads form every stitch: the top thread, which goes through the needle, and the bottom thread, which comes from the bobbin.

A perfect stitch depends on the balance between the two sources of tension on the stitch.

Ideally, the top thread and bobbin thread are drawn equally into the fabric, forming their link in the middle of the fabric layers.

When perfect tension is achieved, the linking of the two threads is invisible, and stitches look the same on the top and the bottom of the fabric.

Too much tension on the top thread (or too little on the bottom) means not enough top thread gets into the stitch, causing puckering and the bobbin thread to show on the top of the fabric.

Too low of top thread tension (or too high of the bottom) means too much thread is drawn into the stitch, causing a loose stitch and the presence of the top thread on the bottom of the fabric.

Thus, sewing tension issues, because they are caused by an imbalance between the pressure on the two pieces of thread, can be caused by inappropriate top or bottom thread tension.

How Top Tension Works

In most cases, two metal discs on the top of the sewing machine control top thread tension.

Also, a spring regulates the pressure on the thread on one side of the metal discs.

This spring is controlled by a dial (or a computer with computerized machines). Increasing the number on the dial increases the tension, or pressure, on the thread.

Your sewing machine tension dial could be located on the top, front, or left side of your sewing machine. Tension numbers commonly range from 0-9 or 1-10 usually.

When the presser foot is raised, the tension discs separate, allowing the top thread to slip between them.

When the foot is lowered to begin stitching, the discs come back together and apply the selected tension to the thread.

This is why you should not thread your machine with the presser foot down.

Since the top thread does not enter the discs, there is no tension. As a result, the top thread is pulled to the back of the fabric, creating loops.

How Bottom (Bobbin) Tension Works

This tension of the lower thread, or bobbin thread, is usually controlled by a screw on the bobbin case.

Most bobbin cases also have a small tension spring on them that you need to pull the thread through when threading your sewing machine.

As a beginner sewist, adjusting the bobbin tension should be one of your last resorts when troubleshooting sewing machine tension problems.

Situations Requiring Tension Adjustment

There are several situations where you may need to readjust your tension before starting to sew.

Examples include:

- Bobbinwork

- Changing thread weight (heavyweight to lightweight or vice versa)

- Switching to a different thread material (such as metallic threads)

- Changing to a different brand of thread

Sewing Machine Troubleshooting Before Adjusting Tension

When troubleshooting a problem with your sewing machine’s stitching, here are some questions you want to ask yourself first before fiddling with the tension.

Because, honestly, many times when I’m sure my Brother sewing machine has tension problems, it turns out to be something else!

1. Is your sewing machine threaded properly?

First, make sure the thread from the spool follows all the thread guides as directed in your sewing machine manual.

Also, make sure you threaded the sewing machine with the presser foot up. If in doubt, rethread!

2. Is the bobbin wound and installed correctly?

Make sure the bobbin is in the correct orientation and that it’s not wound too loosely, tightly, or unevenly.

Also, while you’re looking at your bobbin, check to make sure the bobbin case area is clean and lint-free. If not, clean it out!

I remember the first time I opened this area of my workspace and found many dust bunnies I had no idea were down there.

3. Are you using the correct needle size for your fabric, and is the needle still good?

Choosing the correct needle size matters!

Also, using a bent or dull needle can cause stitching issues. (Check out my exhaustive list of sewing machine needle types and sizes to make sure you’ve picked a compatible needle for your project.)

4. Do you have a thread weight compatible with your needle size and fabric?

Also, in many cases, the top and bottom threads should be identical, so ensure this is the case if you’re having unexpected issues.

5. Have you picked a compatible type of stitch (and adjusted the length and width, if applicable?)

Certain stitches are just not made to be compatible with all fabrics.

Ideally, this will take care of your issues, but if not, you may need to move on to fixing your sewing machine’s tension.

How to Adjust the Tension on Your Sewing Machine

As I mentioned earlier, both the top tension and bobbin tension are adjustable.

When in doubt, start by adjusting the top tension.

How To Adjust Sewing Machine Top Tension

Every sewing machine has a default value for top tension. You should find this value or at least a range of suggested sewing machine tension settings in your manual.

If you’re having tension problems, first try stitching with the suggested value.

Machines usually have tension dials or a computerized interface where tension can be adjusted.

For example, on my Brother CS6000i, here is where this Brother sewing machine tension dial is located.

For most Brother sewing machines, your sewing machine’s tension dial will be in a similar location or at least very easy to locate.

Of course, some newer, more expensive machines will have touchscreen tension adjustments and some will have automatic default tension settings.

Above is the tension dial on my Singer heavy-duty sewing machine. It’s labeled more clearly!

Now to adjust the tension, first do a test stitch.

You want to use both the fabric and thread that you’re planning to use for your project If you have difficulty seeing the stitches, switch to a contrasting fabric with the same characteristics.

After sewing, examine the stitches. You want the knot where the stitches cross to be in the middle of the fabric and for both sides of the fabric to have even stitches. Meaning no loose stitches and no puckering.

If the knot is too far into the bottom of the fabric, you need to increase the top sewing tension to pull the knot up. Remember, a higher number on the tension dial means a higher tension.

If the knot lies too close to the top of the fabric, the tension needs to be decreased so the top thread doesn’t pull the stitch up as much. You will want to pick a smaller number on the tension dial.

Pictures of Incorrect Sewing Machine Tension

Here’s what tension looks like from the front of the fabric when it’s too tight and too loose.

Notice the tight-looking stitches and the fabric puckering when the tension is too high.

Here’s what too tight of tension will look like (up close) on the front of the fabric. See how the knot forms closer to the top of the fabric rather than being invisible in the center?

Here’s what the bottom of the fabric looks like when the tension is out of whack.

Up close, this back of the fabric picture shows too loose of tension will cause the knot to be closer to the wrong side of the fabric.

When you go to adjust the tension, don’t change the dial too drastically. Go one number to the right or left and then stitch again.

Keep doing test stitches until you find that your stitches are balanced.

How to Adjust Bobbin Tension

Unless you know what you’re doing, adjust the bobbin tension as a last resort.

Most sewing machine tension problems are related to the top thread or one of the other possible errors described above.

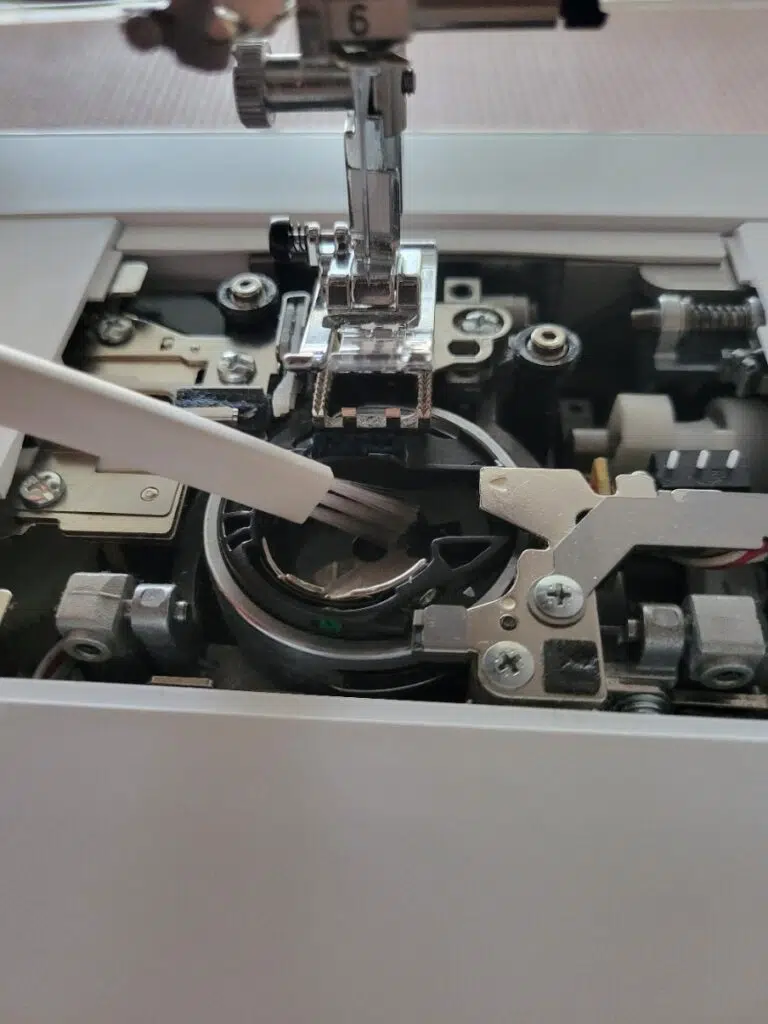

Should you need to adjust bobbin tension, though, first remove your bobbin from the bobbin case.

Using a screwdriver, turn the small screw on the bobbin case.

Only turn the screw a small amount using minimal force. Be careful not to damage the bobbin case.

Turning the screw clockwise tightens the bobbin tension; turning counterclockwise loosens the tension.

How to Adjust Bobbin Tension on a Brother Sewing Machine

See the tiny screw on the bobbin case of my CS6000i sewing machine? I’ve removed the bobbin and pulled the case out from my workspace.

As described above, to change the tension, use a small screwdriver to turn the tiny screw. Make small changes, testing after each tiny turn.

Hopefully, this tutorial will help solve your stitching issues! However, if you’re still having problems after troubleshooting with all these suggestions, it might be time to take your sewing machine in to be examined by a professional.

I am grateful for this post! I couldn’t figure out what’s was happening with my stitches, but your post really helped! Thank you!

Thanks for the positive feedback! I’m glad you could get everything figured out!

This was one of the best articles I read on tension! Thank you!

Thanks for the kind comment!

I have this same exact machine. I am having SERIOUS tension problems. The top tension is too low. I have it turned all the way up to 9.

There are TWO screws on the bobbin case; the regular straight screw off to the left, and the phillips head screw (cross) on the right. Which one gets turned for tension? I cannot turn the phillips head screw no matter what. The flat head screw has green goo all over it. Is that what I turn? Or try to?

I have another question about this machine. Every time I replace the bobbin, like when it gets empty, I refill the same exact bobbin with the same exact thread. Yes it is the right bobbin, the 11.5-mm one. Yes it is set properly in the right direction. Yes the top thread is threaded properly. I had been stitching my project and it was fine. The bobbin emptied, I refilled it, and replaced it in the machine…. and I get a total rat’s nest of bobbin thread when I stitch. I have changed nothing. No matter what I do, rat’s nest!!! That’s when the bobbin thread is not getting caught up on the metal beneath the feed plate.

I don’t get it. I’m ready to chuck this machine.

I am a VERY experienced sewist… been stitching on all sorts of machines for >40 years. No machine has ever given me the grief this one does.

Can you offer any ideas? Thanks.

My father (RIP) who repaired sewing machines gave me very good advise when I too had similar problems; when you rewind the same bobbin or different bobbin put the through a brief cleaning. Take the throat plate off, I use a small paint brush, clean the bobbin casing, feed dog, the teeth, around the bobbin down inside, the needle shaft, and thread guide. Just briefly run it over the machine. Cleaning the tiny dust particles off. Another item about the bobbin, check for gouges in it from the needle, sometimes it brushes against it and put a slight mark on it. He also stated to run the machine really slow watching the action of the needle thread going down and around the bobbin casing, insuring that it is actually going around the bobbin casing properly. I hope this helps.

Hi, I am a new sewing machine user on a Brother GX37 and am trying to follow the Operation Manual to find correct stitch length and stitch width for a zigzag stitch.

The chart in their manual says, stitch name -Zigzag Stitch

Pattern – 3

Stitch Length [mm (inch)] Stitch Width [mm (inch)]

F-4 0-5

(1/64-3/16) (0-3/16)

I don’t know how that relates to the dials for pattern width and length. Would appreciate any help figuring it out. I seem to spend more time reading and watching videos than sewing.

I’ve started sewing a quilt together and the back thread looks like it is puckering. Top tension is on 4. I have never adjusted the bobbin tension. Any ideas?

email: cindy.lively@ymail.com

Thank you for your help. Cindy

My sewing machine is making a loud noises. What should l do? I just got it