9 Helpful Metallic Thread Embroidery Tips for Troubleshooting

This post may contain affiliate links, which means I’ll receive a commission if you purchase through my links, at no extra cost to you. I sometimes receive free products for review. Please read disclosure for more information.

I avoided using metallic embroidery thread as a beginner because I had heard so many horror stories from other machine embroiderers.

But over time, the lure of being able to add a gorgeous sparkle to my embroidery designs encouraged me to give them a try. The outcome was awesome!

The going wasn’t easy at first, but once I learned some basic metallic thread embroidery tips, it became effortless to add shine to my designs.

If you, too, are frustrated with metallic threads, this in-depth tutorial will teach you how to embroider with metallic thread successfully every time.

How Metallic Threads are Made

Let’s start by talking about how metallic embroidery threads are made so you can then understand why they can cause so many issues.

Above, I pulled one apart to show you the two layers! As you can see, metallic threads are made with a layer of metal foil wrapped around a sturdy nylon or polyester inner thread core.

It’s not too difficult to separate the layers by hand, which means your machine will joyfully separate the layers for you if not set up properly.

Despite the wrapped foil, these threads should be relatively smooth to touch. However, if they don’t run through two fingers smoothly, they’re not likely to run through your machine smoothly either!

Why is metallic thread so hard to embroider with?

Think of your machine needle stitching up and down at a fast speed and how this can affect that thin layer of wrapped metal.

If the thread rubs up against the fabric, the needle, or even the inside of the machine too fast, the metal foil can break away.

To make things even more complicated, metallic thread tends to twist, kink, and coil as it comes off the spool (see above.)

As such, if kinky thread reaches the tension disks of your machine, it gets stuck. This also causes the thread to split, shred, and stretch in front of that tension disk.

With the foil splitting away, this leaves just the thread core entering your fabric and the metal foil backing up at the point of blockage.

Ultimately, the inner core snaps soon after the foil is stripped away, and you’re left with a big mess.

Metallic Thread Variations

Threads come in SO many fun, metallic colors, though! There are the usual gold and silver colors, but there are also gorgeous pinks, turquoise, and even variegated metallic threads.

Some machines are temperamental with different brands of metallic thread, so try several to discover which works best.

I’ve used the more affordable Thread Nanny metallic thread with decent-ish results, but the best metallic embroidery thread I’ve found for my machine is KingStar metallic thread. It’s SO expensive but SO worth the lack of hassle it will give you.

Also, the most common thread weight for metallic thread is 40 wt, which is the standard weight for machine embroidery thread.

With some effort, you can find metallic threads in different weights if you want a different thickness of thread for your project. (Learn more about thread weight in this post: types of embroidery thread explained.)

Metallic Thread Embroidery Tips

Now, let’s go through the parameters and process for how to machine embroidery with metallic thread.

1. Choose the Right Needle

When embroidering with metallic thread, you need to switch from a standard 75/11 embroidery needle to a NEW metallic needle or topstitching needle.

Metallic and topstitch needles have extra-large, elongated eyes to decrease friction and prevent metallic threads from shedding and breaking.

Metallic needles also have a larger groove and larger scarf to protect the delicate metallic thread as it passes through the eye of the needle. (Confused about needles? Check out: types of machine embroidery needles explained for beginners.)

In terms of sizes, if you are embroidering on a thinner fabric and using 40 wt thread, start with an 80/12 needle.

If you are embroidering on a thick fabric or using 30 wt thread, start with the bigger size 90/14 needle.

2. Add a Thread Stand or Alternate Spool Set-Up

To prevent kinking of the metallic thread, avoid horizontal thread set up where the thread comes horizontally off the top of the spool. (See below.)

When unwound horizontally like above, metallic thread curls more than when unwound from a vertical position.

Over time, the thread gets more and more twisted until it breaks.

If your machine, like mine, only has a horizontal thread holder, you need to find an alternate way to orient the thread. I have a monster Embroidex thread stand (below) that I use to line up my threads. It also works great for unkinking metallic threads.

I also have a smaller thread stand that works well enough when I place it farther from my machine. I rarely use it, though.

The further (within reason) that you position the thread stand from your machine, the more time the thread has to unwind and relax before it feeds into the machine.

If you can go a foot or two away, that’s great! However, my embroidery space is constrained, so I make do with the space I have.

Simply getting something like the spool holder below to attach to your machine’s bobbin winder will orient the thread better for even feeding.

If you don’t want to purchase a thread stand and instead want to MacGyver it at home, you can even make your own thread holder easily!

3. Thread Nets

Thread nets are common for serger thread and other specialty embroidery threads.

Using a thread net helps obtain even feeding and keeps the thread from falling down the spool and tangling up.

These nylon nets also aim to remove the thread twisting before the thread gets fed into your machine.

I usually have good enough luck without a thread net and just a thread stand, but this is something else to try if you are continually having issues with even feeding. Just make sure the thread net covers the entire cone.

4. Stitching Speed

The faster your machine stitches, the more likely you are to have issues with embroidery thread breaking or shredding.

If you have a very fast machine, I recommend decreasing the stitching to the lowest possible when you first start troubleshooting.

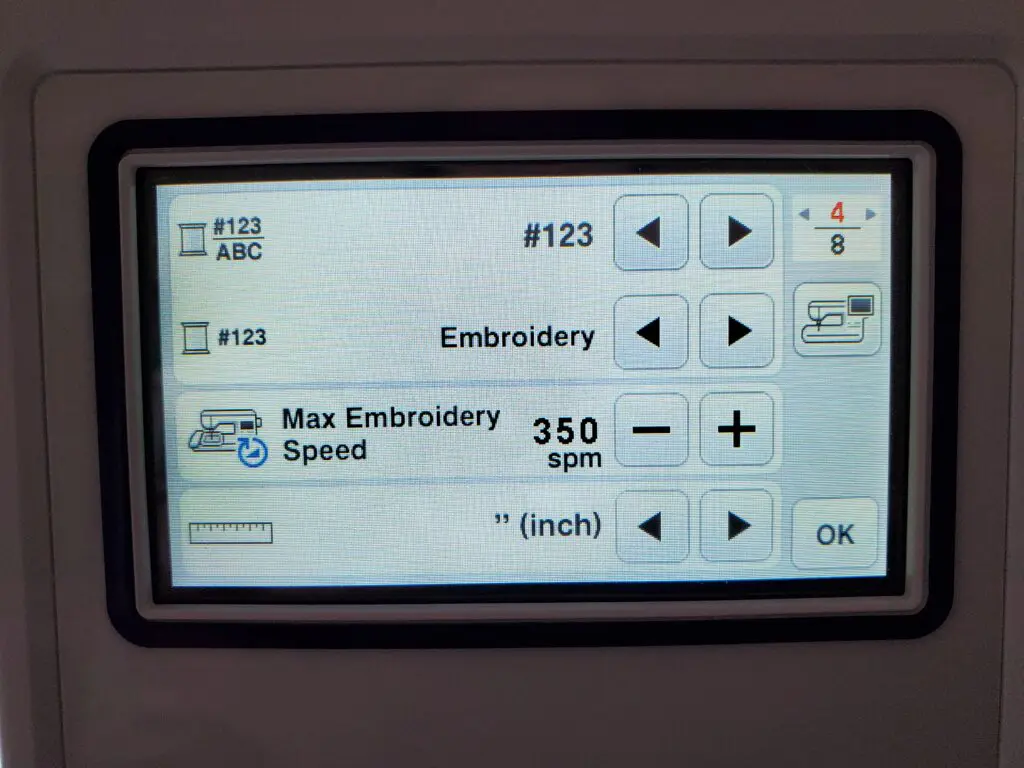

My machine will go down to 350 spm, which is what I use with metallics.

Even though slower stitching means the design takes longer to stitch out, it’s much better than having to rethread every few minutes when threads break!

Slowing down the stitching speed not only decreases issues but also allows you to catch any errors more quickly and fix them before they cause problems with your design.

5. Stabilizers

Choose your stabilizer based on the properties of the design you are using and the fabric that you’re embroidering on.

If you have options, choose a cut-away or no-show mesh instead of a tear-away stabilizer. T

he former two types are softer and more pliable, meaning slightly less possibility for shredding as the thread continually pierces through them.

Also, avoid adhesive stabilizers and even using adhesive spray, if possible. Avoid anything that might pull that outer shell off.

6. Thread Tension

As the metallic embroidery thread unwinds off the spool, it soon reaches the tension disks of the embroidery machine.

Loosening machine tension decreases friction at these discs, preventing stretching, backup, and ultimate breakage of the thread as it passes through.

Thus, embroidering with metallic thread is one of the few times where you may need to loosen your machine’s tension to achieve the best results.

This adjustment will be machine-specific, fabric-specific, and even specific to the brand of thread, so there’s no set “best” tension for metallic threads. Your user manual will have instructions for how to adjust your machine’s tension from default tension.

Make small changes rather than big changes at first.

Without doing a stitch-out, you can test how tension changes affect thread feeding by trying to pull your thread through the machine by hand with every change you make.

7. Design Selection

Pick designs carefully when using metallic machine embroidery thread. (And, always do a test stitch before you start embroidering on an expensive or irreplaceable fabric.)

For instance, dense designs with overlapping stitched areas may not work out the best. S

titching through an extra layer of stitches in addition to fabric and stabilizer makes the thread more likely to catch and break.

I usually like stitching most of my designs in regular embroidery thread and adding metallic thread at the end of a final pop of detail.

There are certain instances where it won’t be as obvious that you’re using metallic embroidery thread. For instance, black metallic embroidery thread…looks like regular old black polyester embroidery thread to me!

8. Clean Out Your Machine

If you can’t troubleshoot your problems easily, clean out the bobbin case and examine the upper thread path for any debris.

Sometimes this simple fix can make all your embroidery headaches go away!

9. Automatic Thread Cutter + Cutting Jump Stitches

If you embroider frequently with metallic threads, consider turning off automatic thread cutting.

The reason for this is those wiry metallic threads can blunt the blades of your built-in thread cutter. Meaning, you have to replace it sooner.

When it comes time to trim jump stitches, you might have more difficulty because the threads are thin and unruly.

I recommend a nice sharp pair of curved tweezers (like mine below) to get underneath the jump threads and help hold loose ends away from the fabric.

Then, snip with a small, sharp pair of scissors.

Uh-Oh: Fixing Errors From Metallic Thread Shredding

If your thread starts fraying and doesn’t break immediately, you might notice areas with poor stitching color and quality.

Since the foil’s backed up somewhere in the machine, you’ll get areas that have just plain thread in them.

If you want to fix these areas and not start a new project, simply restitch over that section!

Use the interface on your embroidery machine to move back as many stitches as needed until you find the place where the threads frayed. Then, have your machine start stitching again.

Any other metallic thread embroidery tips you want to share?

Very good read, Thank you for your helpfull tips

Thank you I’m ordering my metallic needles and giving those beautiful threads in my stasha go.

I have purchased madeira 40 weight metallic thread. This article was extremely helpful. The stabilizer suggestions are extremely helpful. The whole overall article covers every thing needed to know when sewing with metallic embroidery thread very well.

Thank you so much for posting this.

That was a great article. There isn’t much help out there for embroidering with metallic thread, so I really appreciated getting all the information you included. I’m making Christmas cards and was having lots of trouble with my thread, but I think I know how to do it now and my cards will look great.

Thanks and best wishes on your Christmas cards!

This article probably saved me hours of frustration as a first time metallic user. Thank you so much!

Glad it was helpful–best wishes with your metallic thread!